Thermal Fluid Systems, Inc. offers custom design of thermal fluid, steam, and glycol process skids, providing heating and cooling operations and accurate control of temperatures to ± 1°F (0.5 °C). Heating media includes thermal fluids such as Chevron, Dowtherm, Essotherm, Texatherm, and Therminol, along with steam and glycol. Cooling media includes water, chilled water, air, and other methods. The process skids are composed of controls, secondary loops, pumps, and valves. Customers can choose from field installation or pre-built assembly, as well as customized mounting or completely skid-mounted units.

All custom-engineered process skids are built to exacting standards, upholding the rigorous industrial regulations for quality and functionality. Our designs are flexible, meeting the particular specifications of customer applications. All products uphold the rigorous standards of quality and performance set by industry regulatory boards, including ASME, FM, and ASI, along with our internal quality assurance protocols.

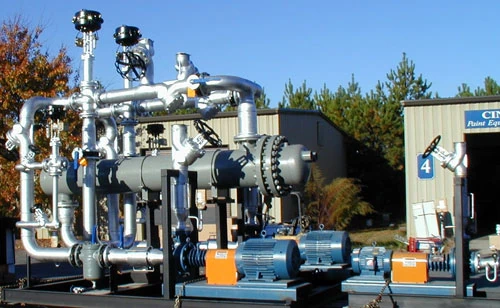

Thermal Fluid Skid System

Our customized thermal fluid skid systems are used in a wide variety of industries to provide thermal energy for process heating, space heating, or cooling. Thermal fluid skid systems consist of a pump, heater, and cooler connected by piping to a heat exchanger. The pump circulates the thermal fluid through the system and is heated or cooled as needed by the heater and cooler.

Thermal fluid skid systems are an efficient and cost-effective way to provide thermal energy for a variety of applications. Thermal fluid skid systems are easy to install and maintain and can be customized to meet the specific needs of your application.

Glycol Skid System

Glycol skid systems are used in a variety of industries to provide a safe and efficient way to transfer glycol from one location to another. A few key components make up a glycol skid system, and understanding how each one works is essential to ensuring the system runs smoothly.

- Pump: The pump is responsible for moving the glycol from one location to another.

- Piping: The piping is responsible for connecting the various components of the system, and it must be made of materials resistant to corrosion.

Different types of pumps, tanks, and pipes can be used in a glycol skid system. It is essential to consult with an expert to determine which type is best for your specific application.

Glycol skid systems are an essential part of many industries, and understanding how they work is crucial to ensuring that they operate correctly. These systems are designed and built with a variety of different components, each of which plays a vital role in the overall operation of the system. Pumping glycol from one location to another and connecting the various components together with piping are all essential aspects of these systems. Consulting with an expert to ensure that you select the right components for your specific application is necessary to ensure that your glycol skid system runs smoothly.

For more information about the design and supply of custom thermal fluid, steam, and glycol process skids or the other value-added capabilities available, please see the table below or contact us directly.

Thermal Fluid, Steam & Glycol Process Skid Capabilities

| Temperature | +/- 1°F 0.5°C | |

| Operation | Heating Cooling | |

| Heating Media | Thermal Fluid Steam Glycol | |

| Cooling Media | Water Chilled Water | Air Other |

| Services | Design Supply Maintenance Plan | |

| Maintenance Inspection | Check all Operating and Safety Controls Check Heater Ancillary Equipment | Review Operating & Maintenance Procedures Operator Training |

| Components | Secondary Loops Pumps | Valves Controls |

| Assembly | Pre-Assembled Field Installation | |

| Operating Temperature | 200 to 750°F | |

| Design Temperature | 750°F | |

| Operating Pressure | Pumping Pressure (No Internal Pressure) | |

| Design Pressure | U to 300 psi | |

| Thermal Fluid Type | Mineral Oil, Synthetic or Specialty Calflo Chevron Dowtherm Essotherm Glycol Marlotherm Mobiltherm Multitherm | Paratherm Petrotherm Shell Thermia Syltherm Texatherm Therminol Water Xceltherm Others |

| Voltage | 480 to 575 V | |

| Phase | 3 | |

| Frequency | 50 to 60 Hz | |

| Accuracy | +/- 1°C | |

| Location | Indoor Outdoor | |

| Mounting | Skid Customization | |

| Class | General Hose-Down | Class I Class II |

| Division | I II | |

| NEMA Rating | 1 3R 4 | 4X 7 12 |

| Materials | Carbon Steel | |

| Testing | Pressure Function (Controls) | |

| Additional Services | Field Service Annual Inspections Start Up | Engineering Consultation Replacement Parts |

| Production Volume | Prototype to complete production system | |

| Lead Time | 3 to 4 months |

Additional Information

| Industry Focus | Plastics Chemical Food Industry Laundry Asphalt | Chemical Food Industry Laundry AsphaltPetrochemical Pharmaceuticals Process Equipment Specialty Paper Textiles |

| Intended Applications | Heated Rolls Calendar Rolls Press Platens Process Skids Wood Presses Reactors Heat Exchangers Dryers Evaporators Mixers Laminating Presses Printing Machines Coatings Molding Presses Edible Oils Sludge Drying Rubber Presses | Adhesives Tank Heating Dryers Reactors Fuel Heating Heat Exchangers Ovens Cargo Heating Fluidized Beds Fryers Heat Tracing Kilns Dry Kilns Chemicals Wood Board Plants Tenter Frames Remediation |

| Industry Standards | ASME FM ASI | |

| File Formats | AutoCAD Inventor |